A majority of our customers are world leading compaines or specialized within their field; constantly facing challanges in new solutions and drive technology forward. With over 20 years of manufacturing experiance we help our customers design their products to be come more friendly for manufacturing; lowering costs significantly and creating competitive edge for them.

Being innovative and with great understanding of manufacturing in; casting, forging, machining and metal production processes makes us a ideal partner in product development and cost-reduction projects. Below are real actual cases developed with world leading companies (ref. are shared upon request).

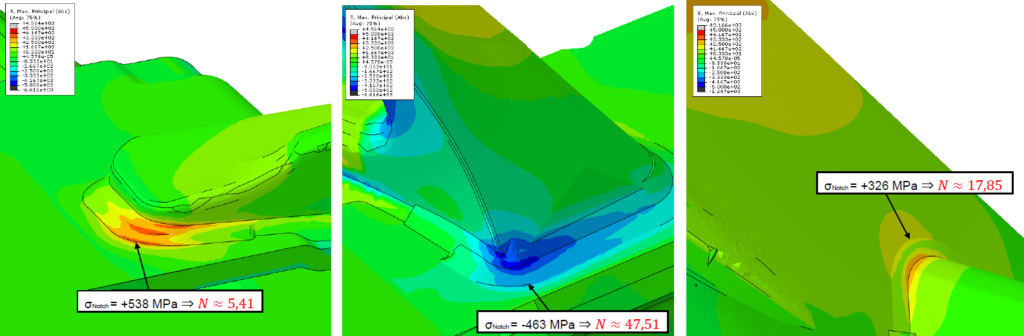

Cracking bracket

Our customer a multi billion company leader in their business field; Their goal was to develop a stronger bracket for their new equipment. Howshun’s development engineers selected a steel material friendly for welding and with great properties in tensile strength. Additionally strain calculations was made to simulate how the forces effected the bracket and the calculated overload which it would fail. With the data collected after simulations, the geometrical shape was redrawn to divide the tension away from the weld. This development project increased the bracket life time by 47 times.

Burrows and badgers

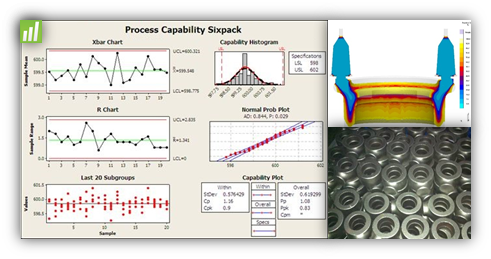

Our customer, a world leading OEM in construction equipment had issues with their cylinder rods. A small procentage had porosity exposed after final machining. With tighter inspection and cpk-anaylsis the problem was still persistent for years. The company started to work with Howshun and they shared the product history.

Howshun started to look into the root cause and the liquid flow along with solidification in the casting process. It was discovered the parts was a reconstruction from previous welded part with unfriendly geometrical dimensions inherited. A new design with casting friendly radius, reducing bottlenecks and general geometrical shape was suggested after excessive simulations. The end results was very stable and successful, a new cpk concluded minimal risk for porosity, reaching over 1.67 cpk.