ASTM A 802 SCRATA – Comparators for the definition of surface quality of steel castings

When it comes to deciding the level of quality for a surface, it is very hard to define it by using numbers and words, therefore a compare-method is more suitable. This standard is available for non-disclosure download for our customers and the SCRATA plates are also available at our quality department for use.

The quality or product manager can specify on the casting drawing desired level of quality. Howshun will inspect all castings accordingly to ensure the surface quality meet customer demands.

ASTM A 802 standard is used as a standard to define the accepteance level for surface quality and requirements. The quality of a steel casting surface defined with nine different categories, each with five quality levels, decreasing from 1 to 5 (i.e. level 1 is the highest and best quality requirement)

The nine categories are:

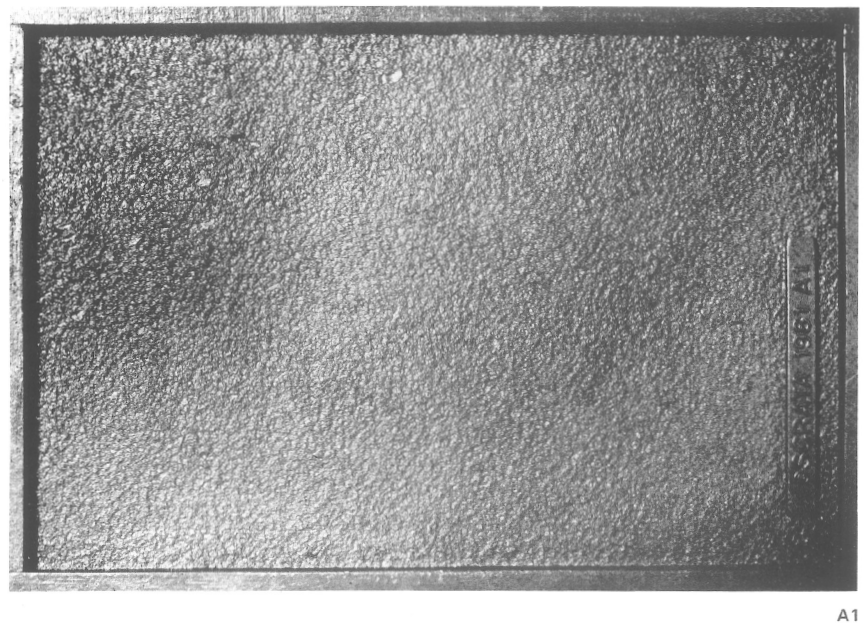

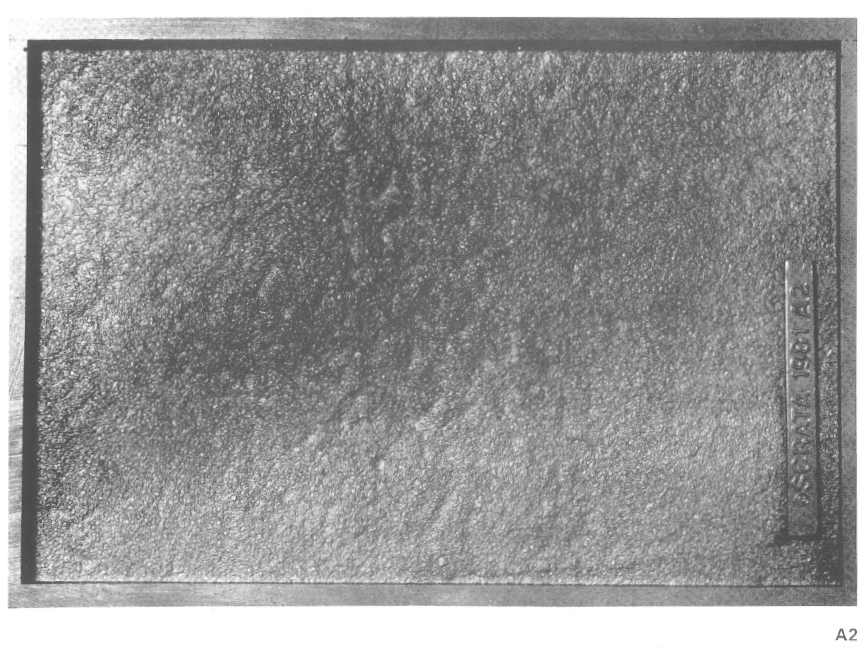

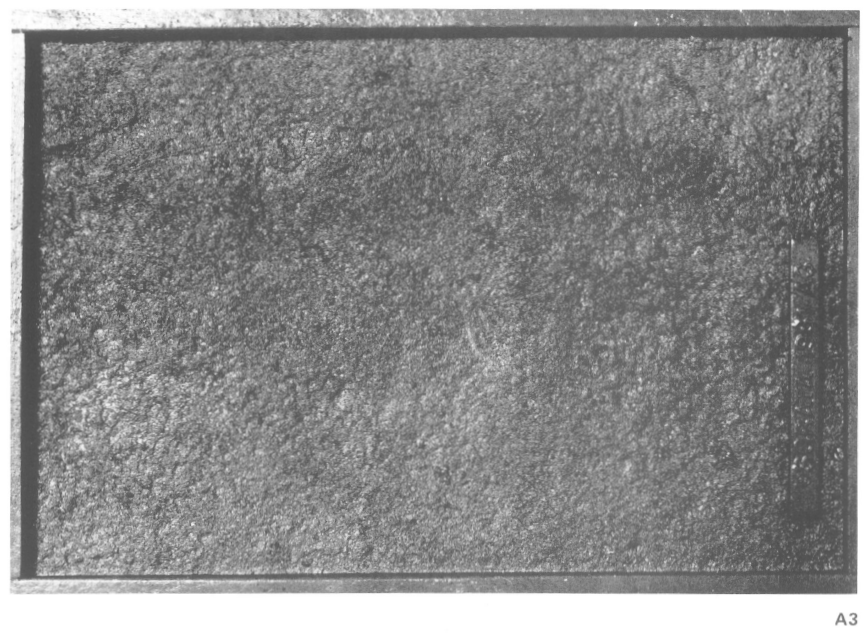

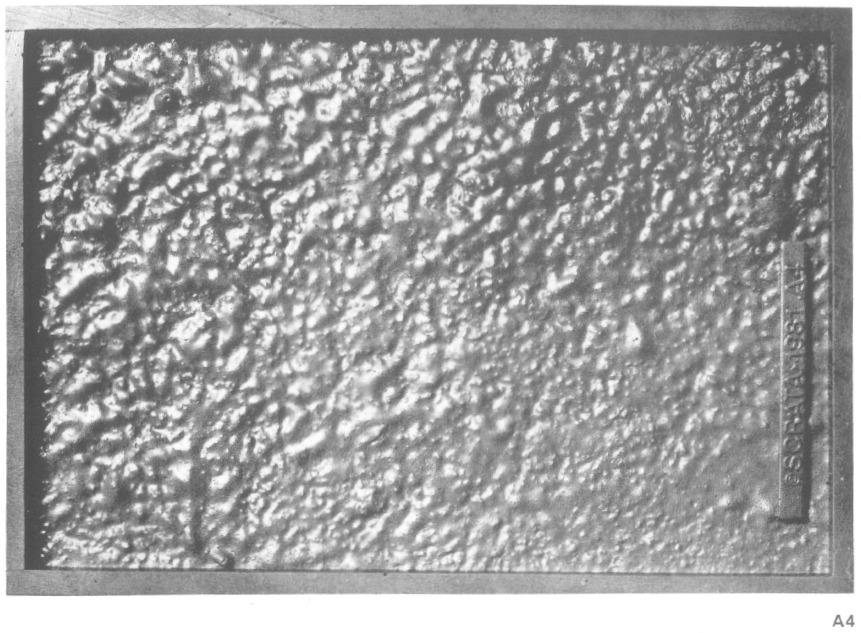

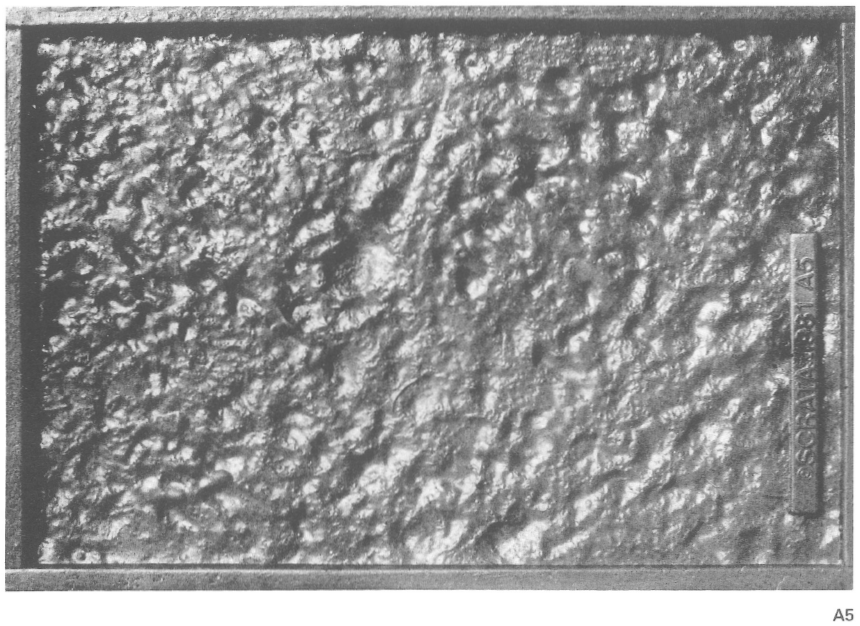

A. Surface Roughness – The natural surface of the casting after shot blasting.

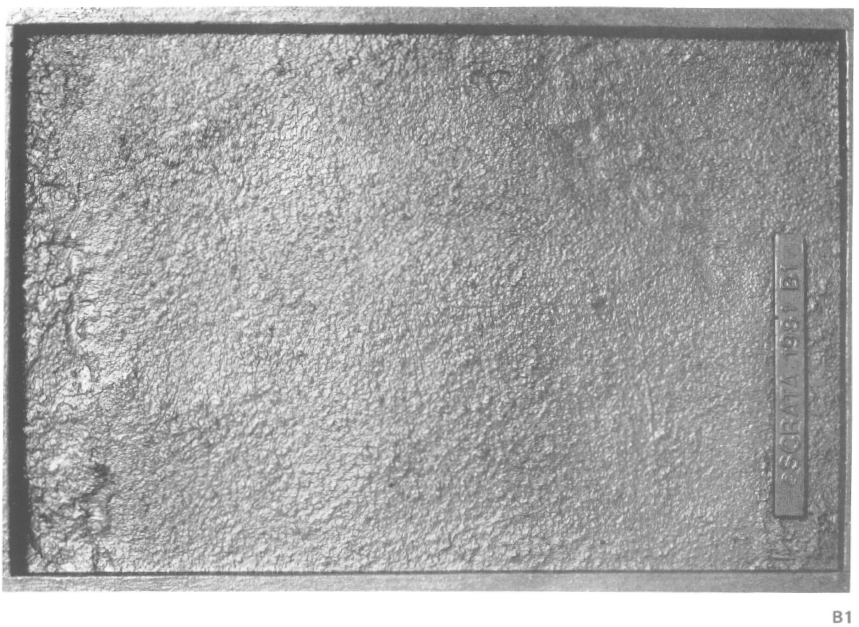

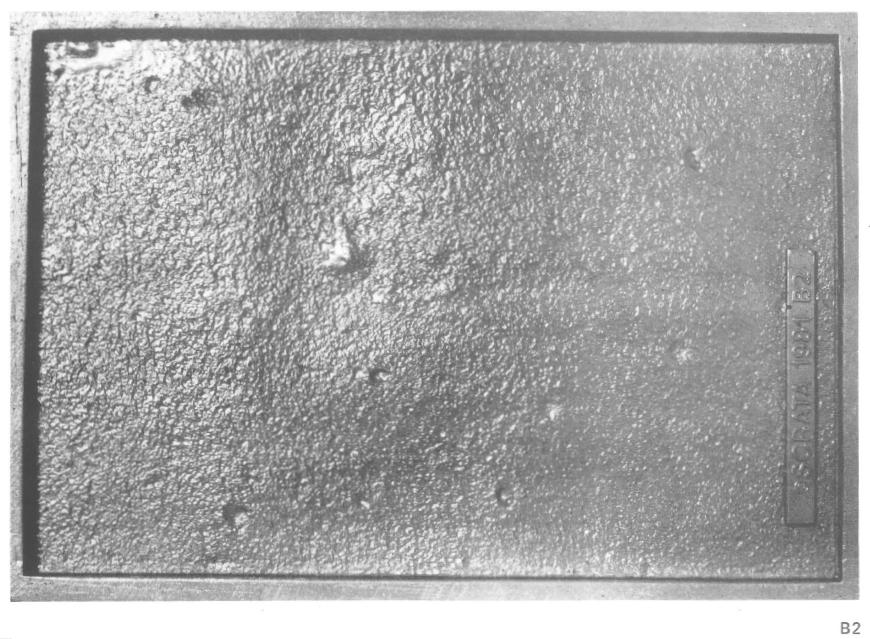

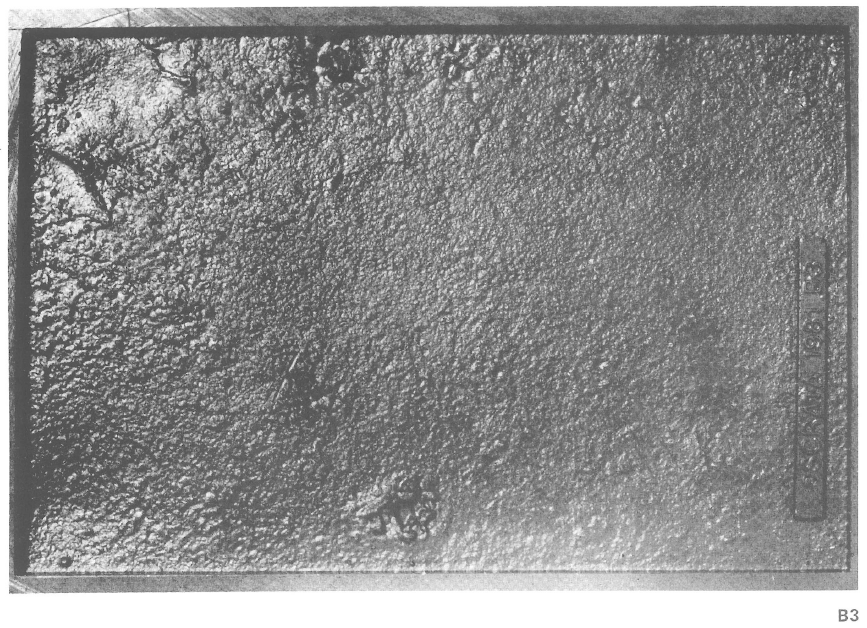

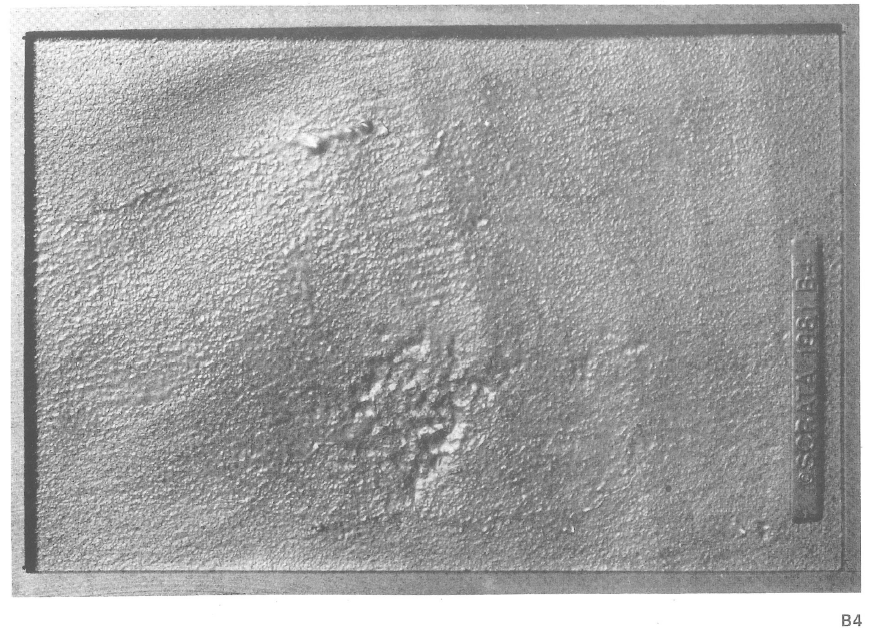

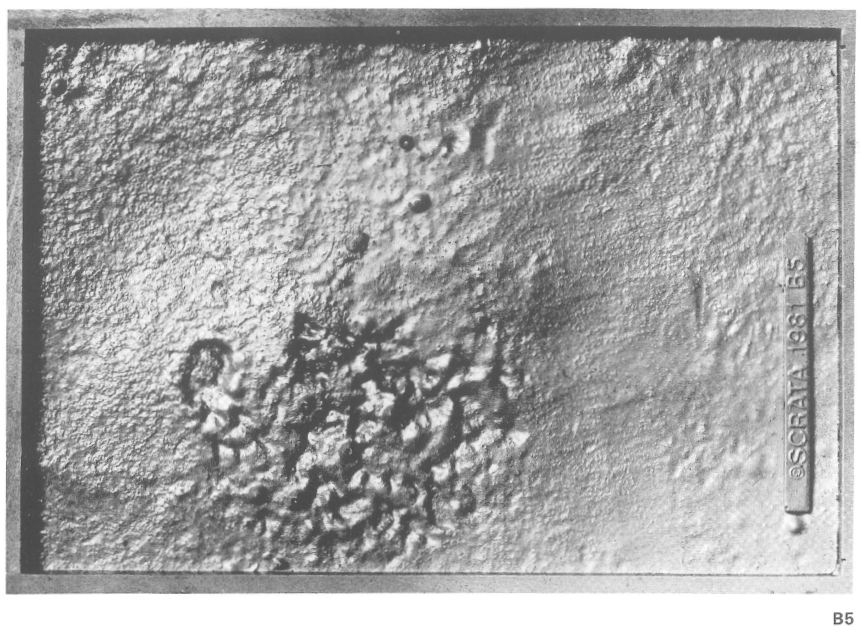

B. Surface Inclusions – Non-metallic material trapped on the casting surface.

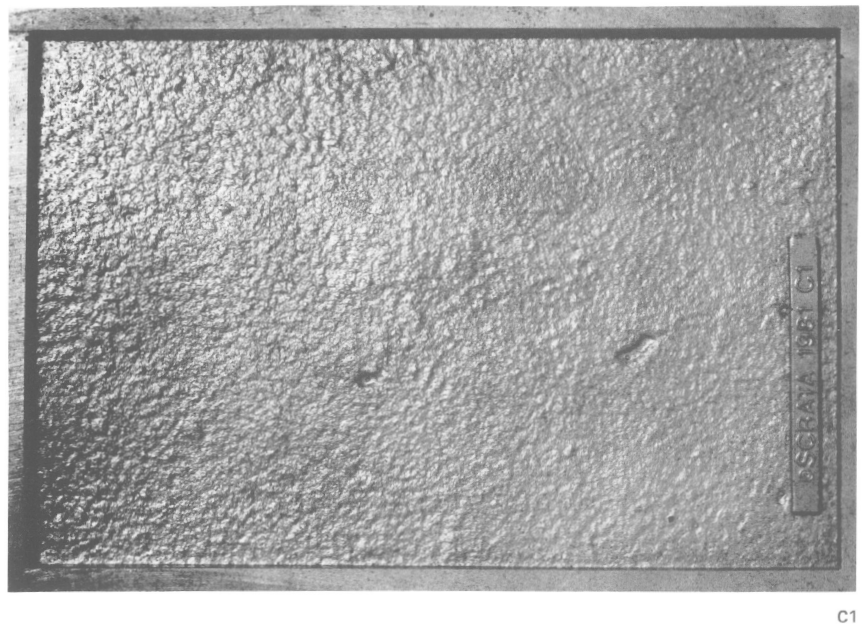

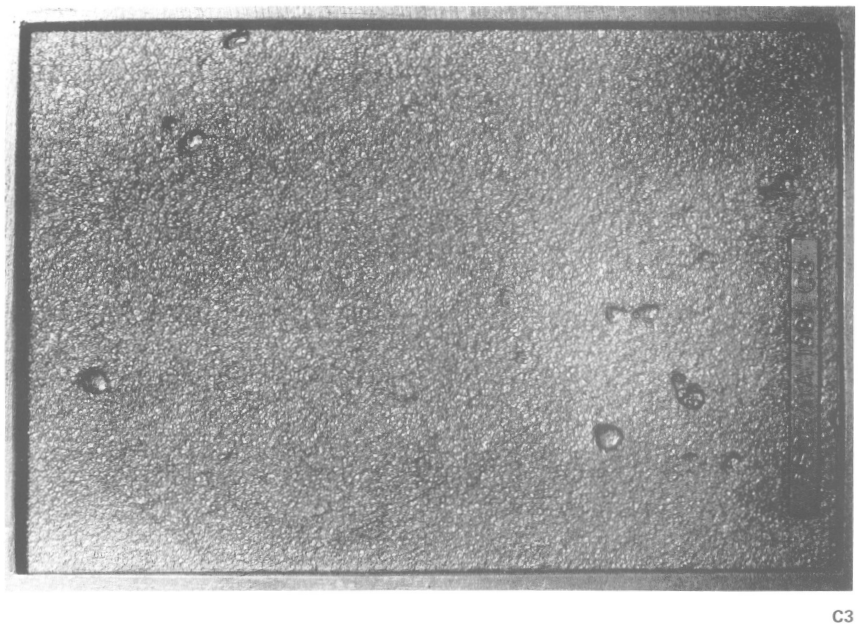

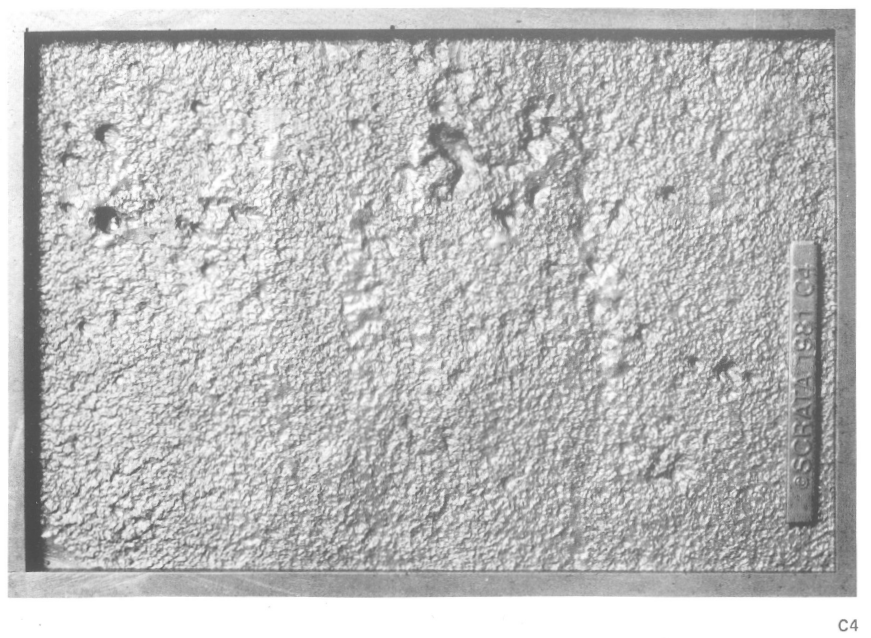

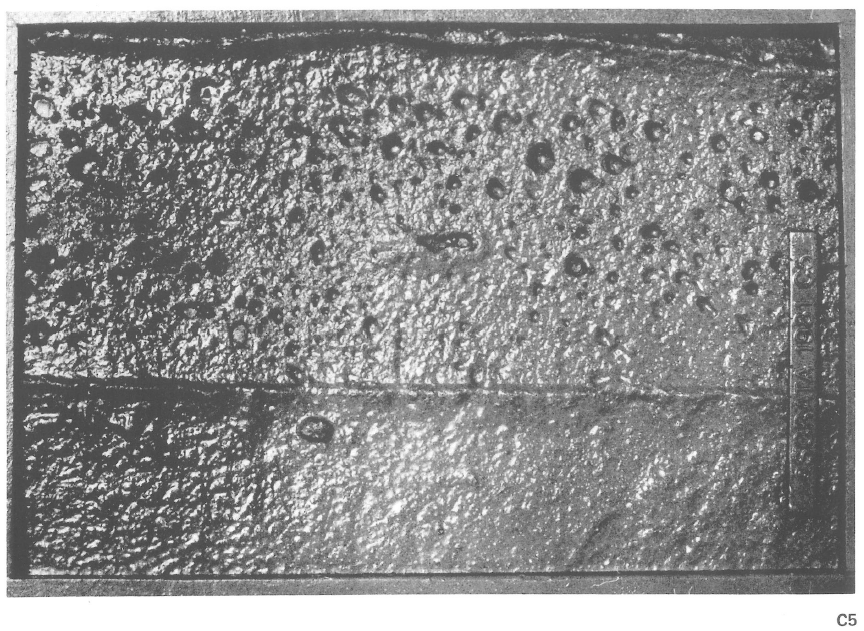

C. Gas Porosity – Indications of gas at the casting surface.

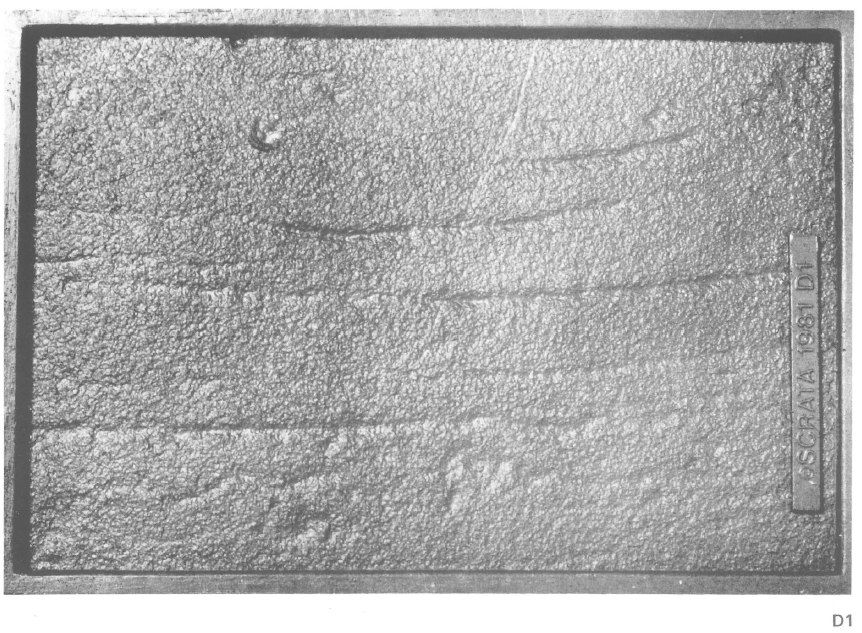

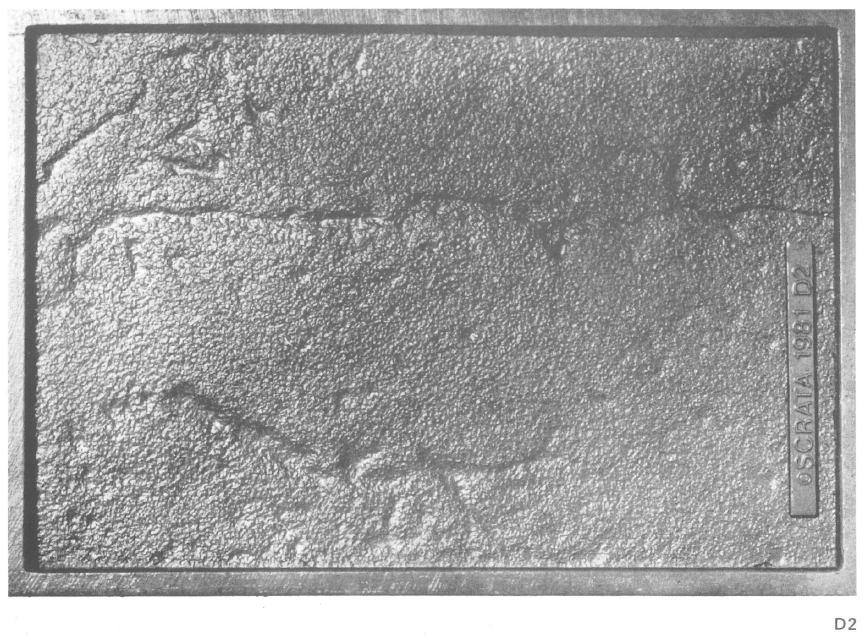

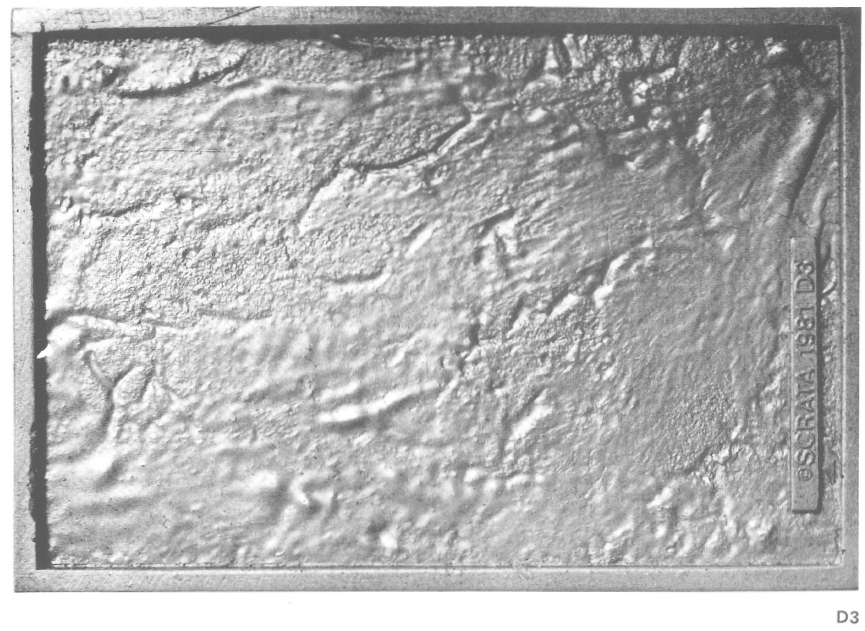

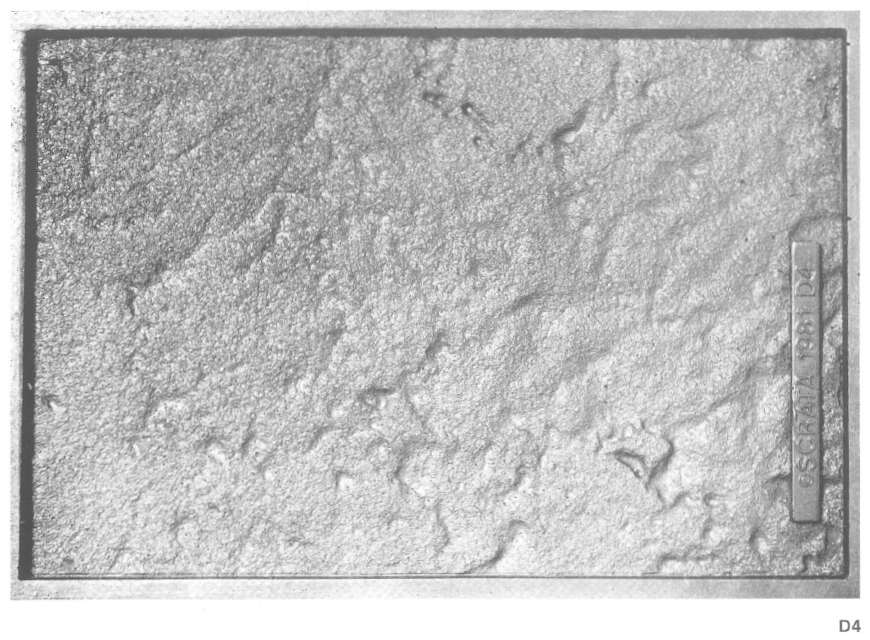

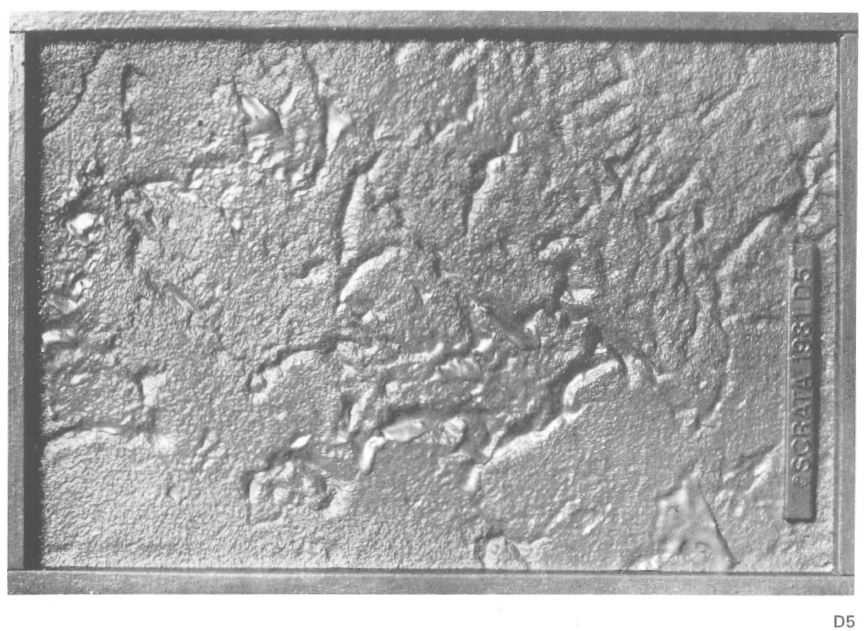

D. Laps and Cold Shuts – Surface irregularities giving a wrinkled appearance.

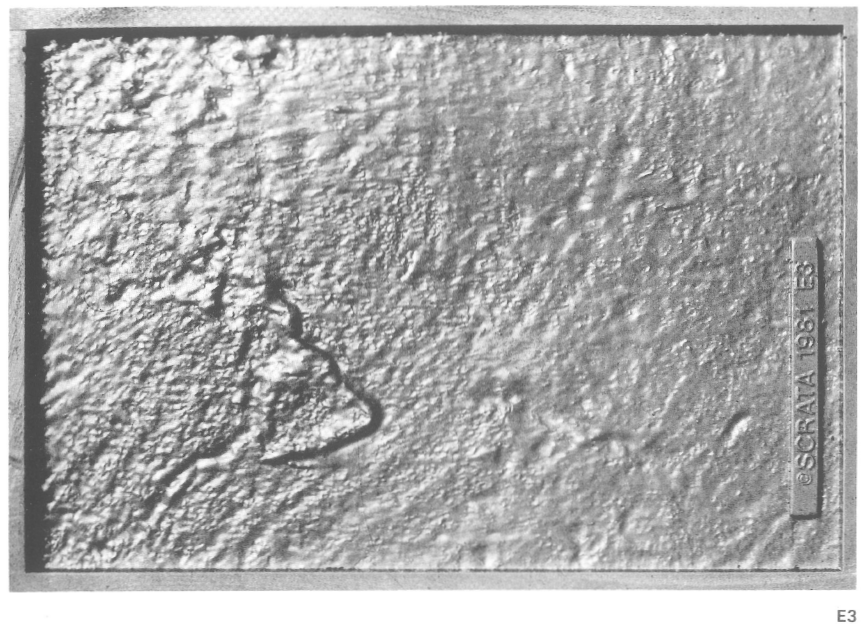

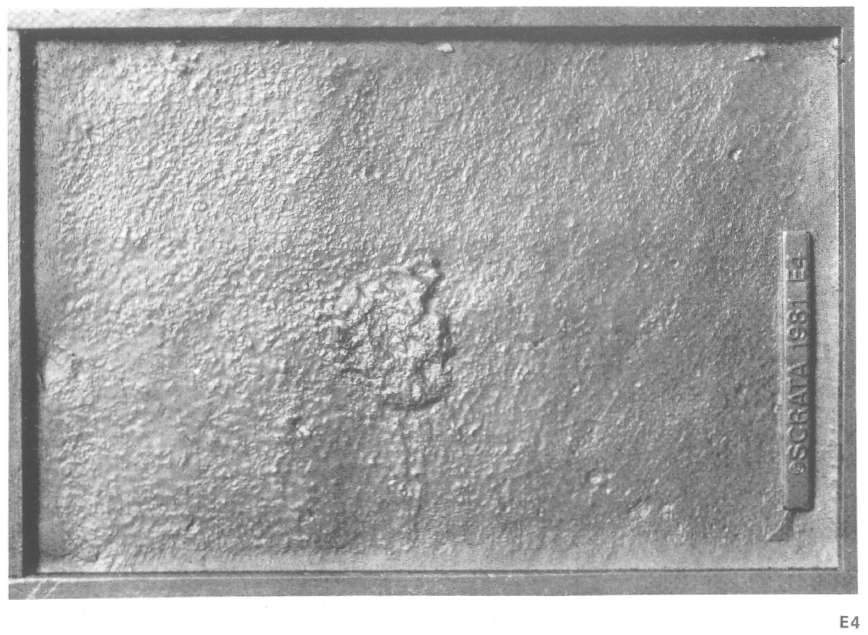

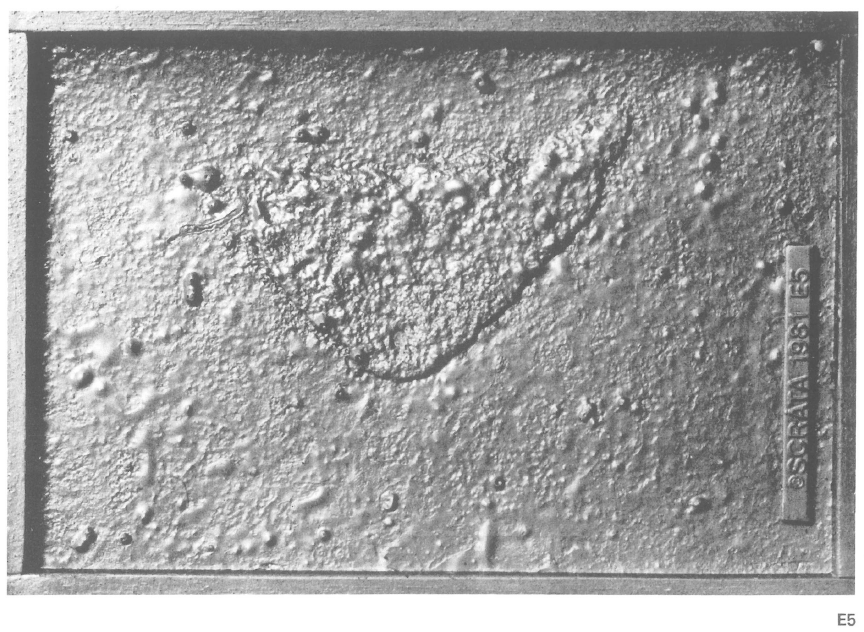

E. Scabas – Slightly raised surface irregularities.

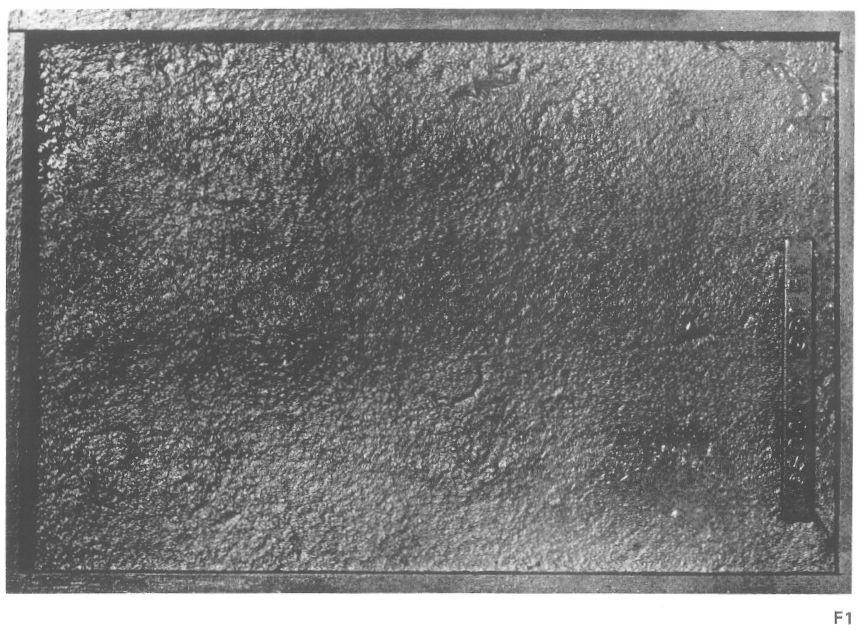

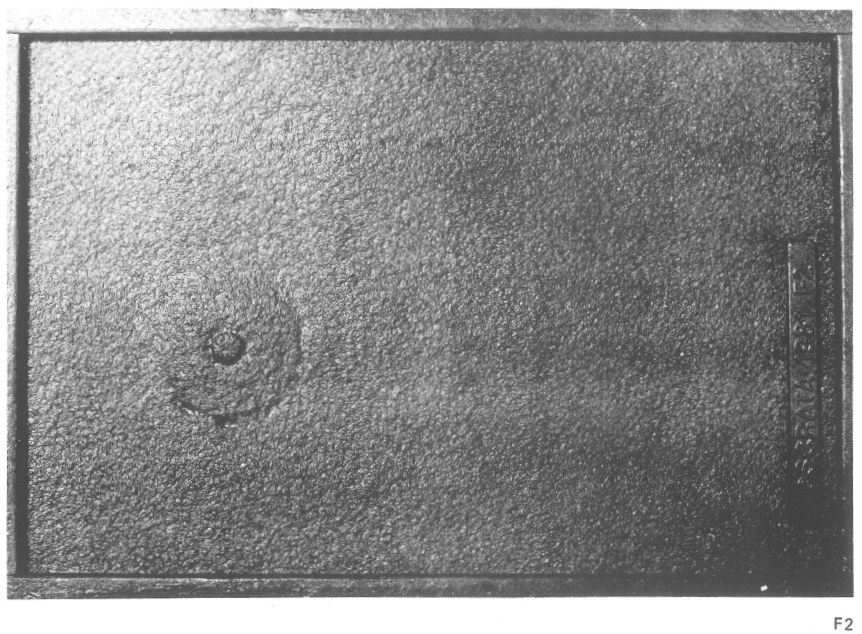

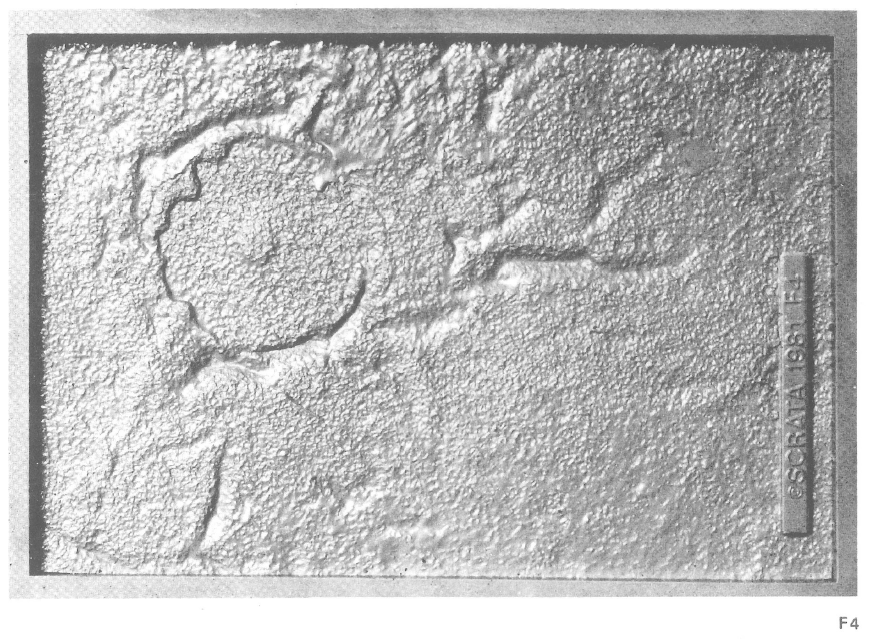

F. Chaplets – Indications of chaplets or internal chills.

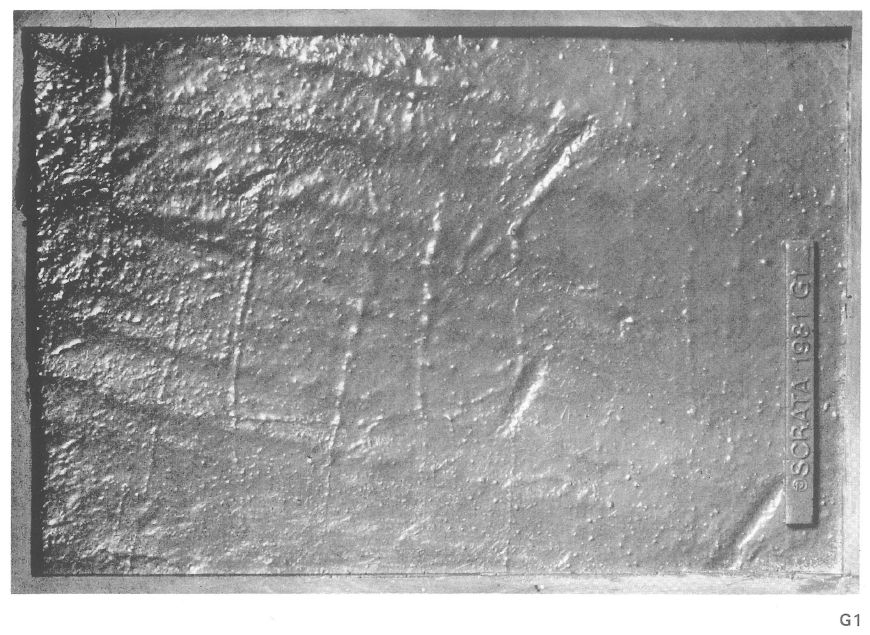

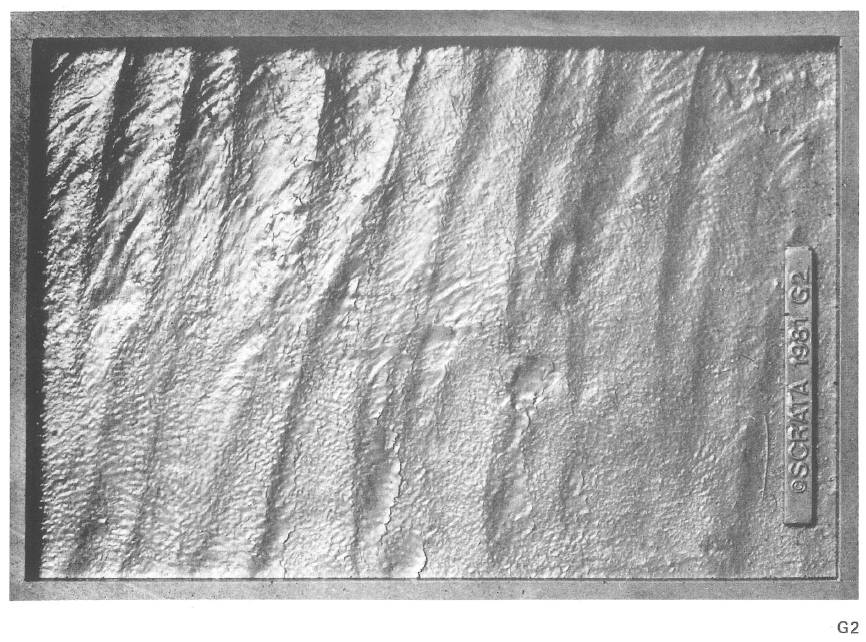

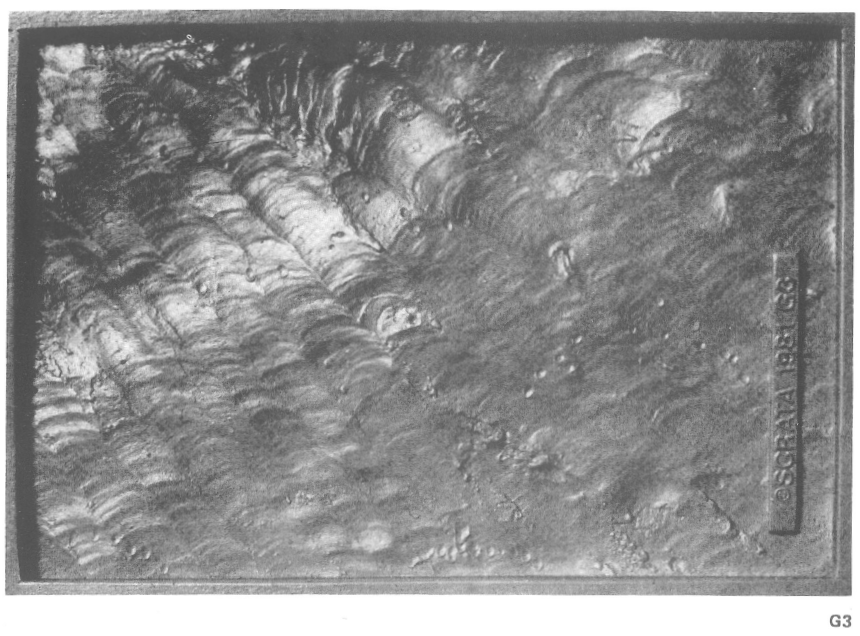

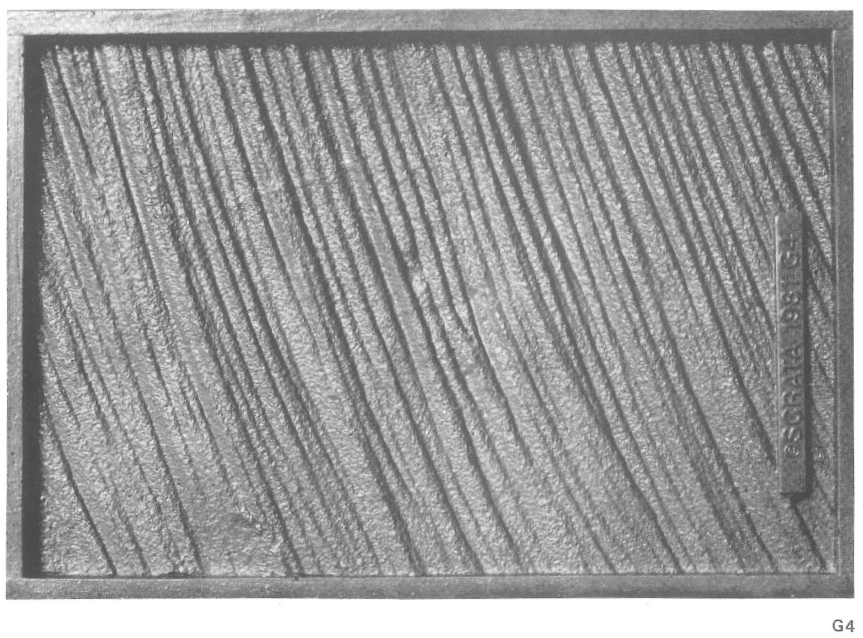

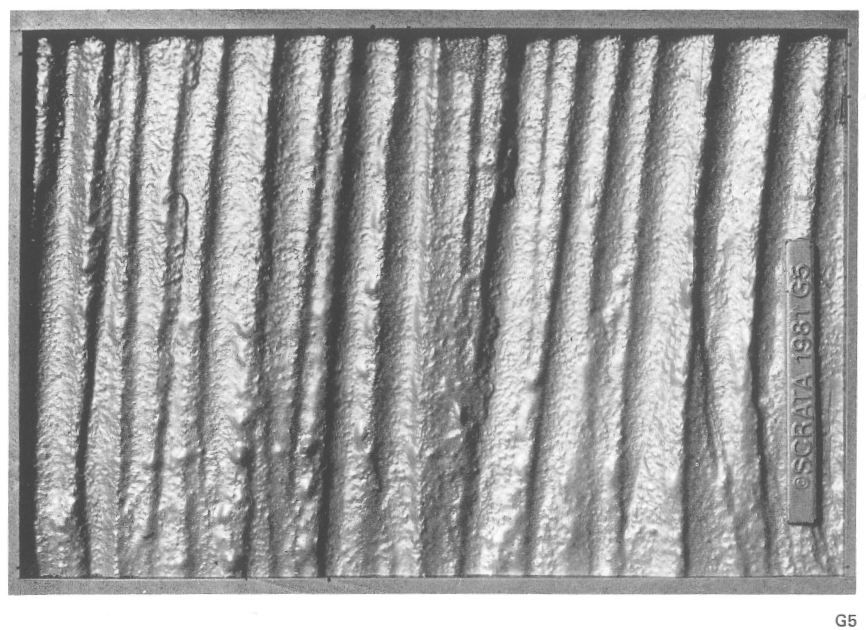

G. Surface Finish / Thermal Dressing – Surface remaining after using oxy-gas or air-carbon arc processes for metal removal.

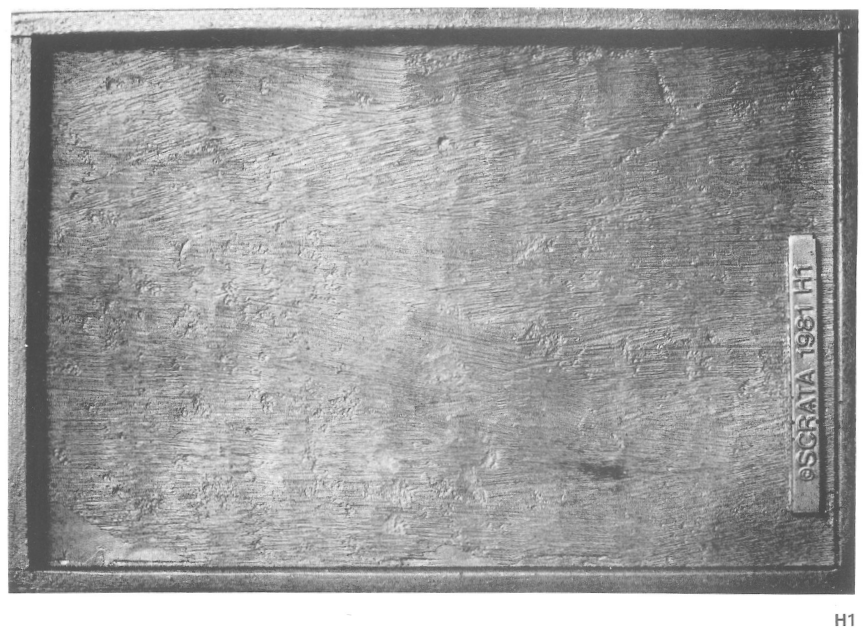

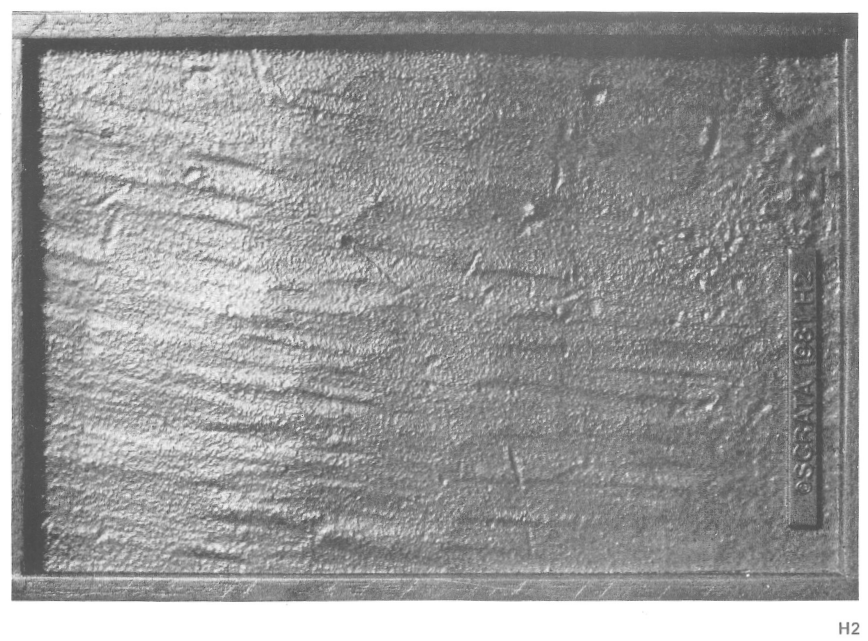

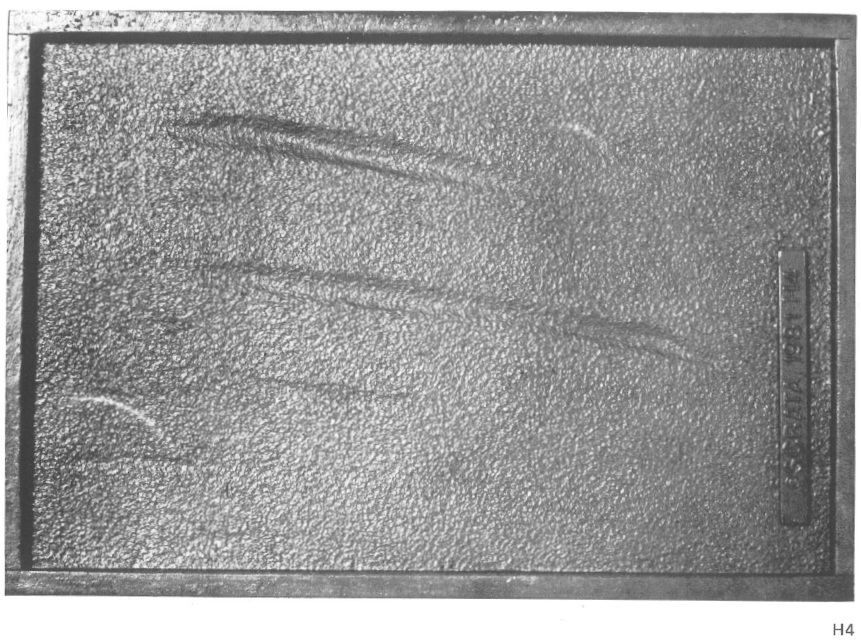

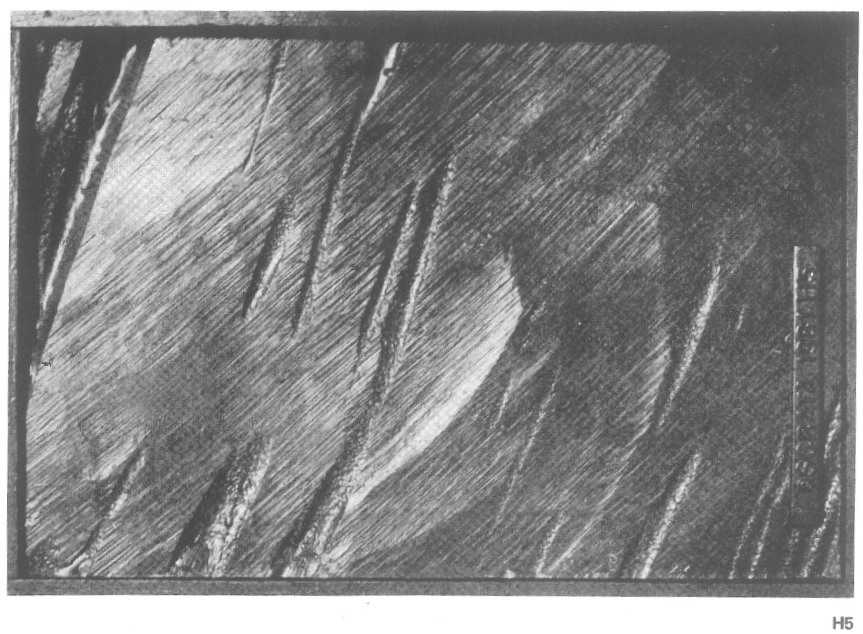

H. Surface Finish / Mechanical Dressing – Surface remaining after using a mechanical means of dressing a cast surface or a previously thermally dressed surface.

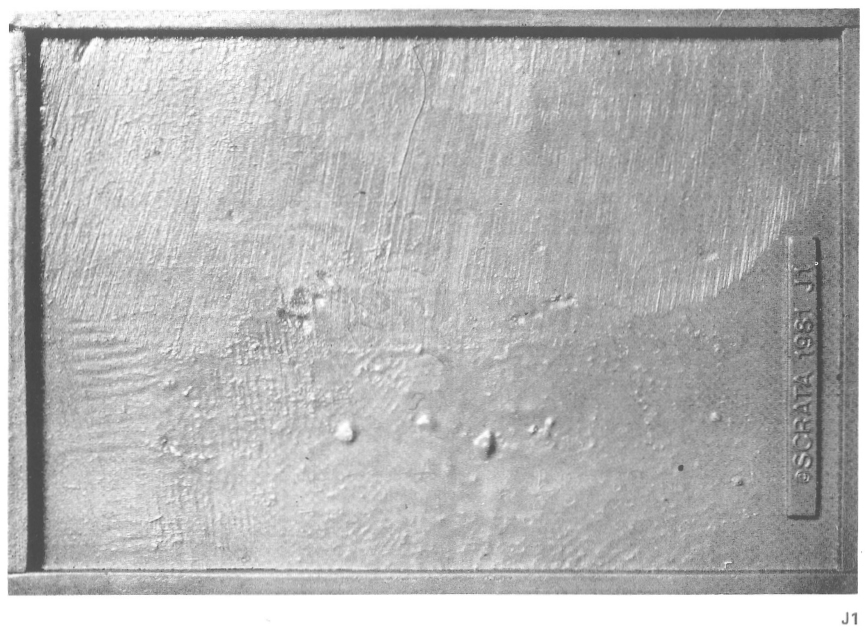

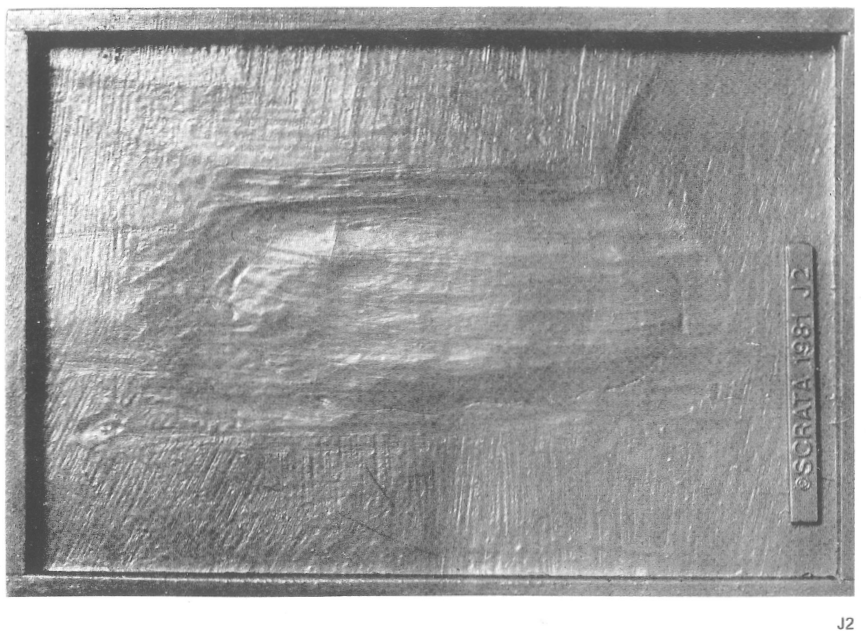

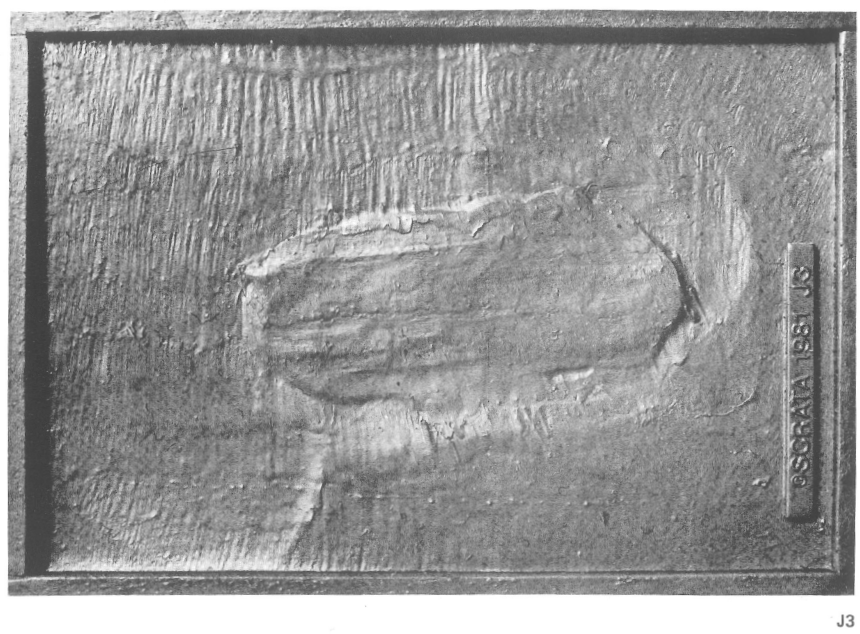

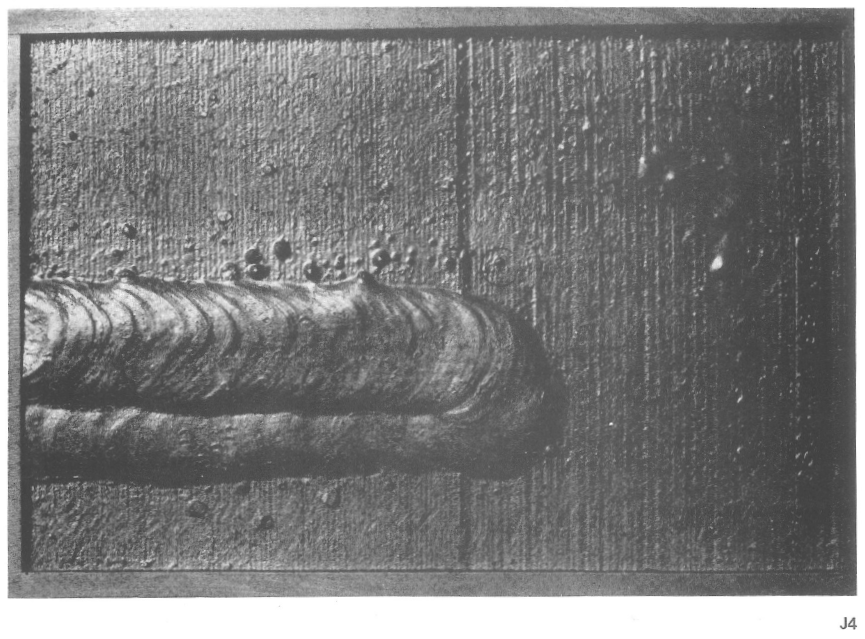

J. Welds – Indidations of welds fully or partially removed by thermal or mechanical dressing.

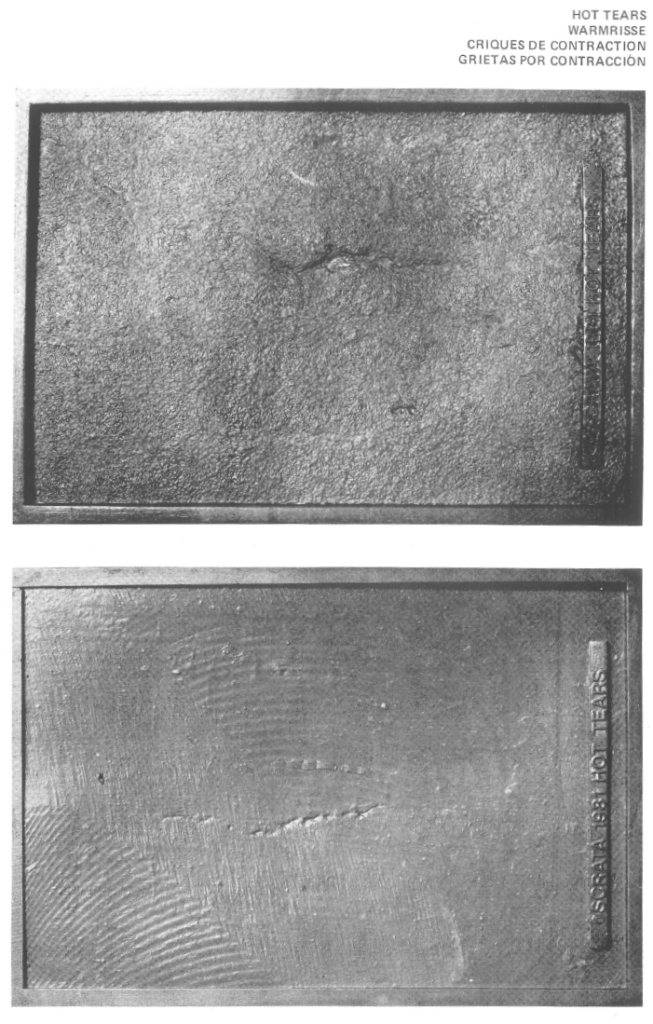

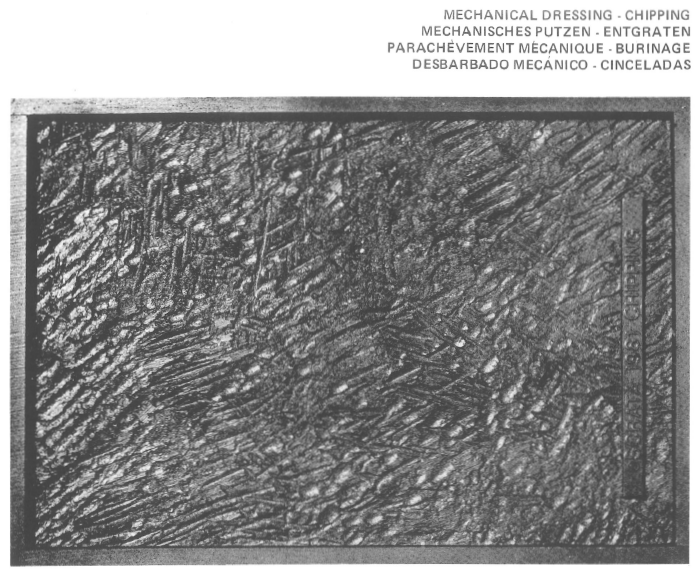

The following are only as example and has not been graded into quality levels, hence this acceptablity should be subject of agreement between foundry and the purchaser.

Hot Tears – Linear surface discontinuties initiated during the final stages of solidification.

Mechanical Dressing / Chipping – Chisel marks remaining after dressing large castings.