Who Are We

Howshun Group

Houshun is a privately-owned engineering and manufacturing business group catering to OEMs and customers seeking a tier 1 supplier with expertise in product development, foundry operations, forging, and machining workshops.

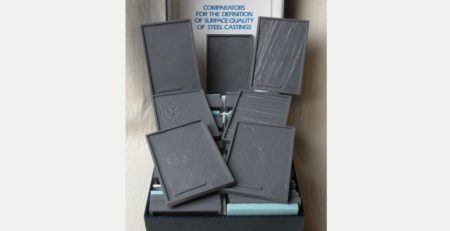

With ISO 9001, IATF (TS) 16949 certifications, and over 20 years of experience in the production of metal castings (primarily in grey iron, ductile iron, steel, and aluminum), forging, and machined products, we specialize in developing and delivering high-quality, secure products for discerning customers.

Services

We offer product development and manufacturing services that meet your demands

Blog

We want to share our latest news and experience in manufacuturing.